Application Method for wet grinding:

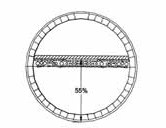

Typically,the quantity of alumina ball loaded into the ball mill is not less than 55% of the total ball mill volume.

Empirical formula of alumina ball quantity fed into ball mill

M=3.14أ—R2أ—Dأ—Lأ—25%أ·1000

M:alumina ball quantity D:Alumina ball gravity

R:Ball mill barrel radius L:Ball mill barrel length

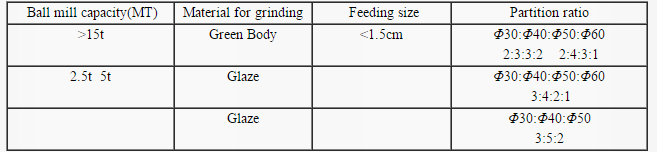

Alumina ball partition ratio

For a new installed ball mill,the alumina ball partition depends on the capacity of the ball mill and the granular size of the material for grinding.

Alumina ball make-up quantity=Primary ball quantity أ—abrasionأ—Grinding time

Application Method for dry grinding

Application Method for dry grinding

Dry grinding is widely used in mining,ceramics,powder and many other industries.For the grinding media stains the raw material in the powder industry,we use some imported raw alumina powder for design and production of alumina balls for dry grinding,with better toughness and resistance.This is a solution to the material contamination caused by grinding media in powder industry.

alumina ball quantity fed into dry-type ball mill

alumina ball quantity fed into dry-type ball mill

The quantity of alumina ball for differenct ball mills as below:

Ball mill for ceramic industry:M=3.14أ—R2أ—Dأ—Lأ—25%أ·1000

Barrel mill for powder industry

Stirring mill:

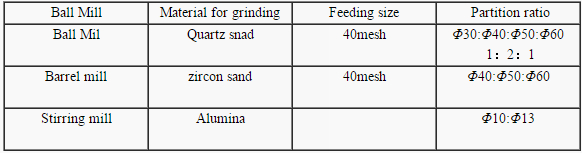

Alumina ball partition ratio

Alumina ball partition ratio

The partition ratio of alumina ball for dry-type ball mill depends on the harness and feeding size of the material to be grinded.Generally,the forming method is cold isostatic pressing(CIP)

Test method of Microcrystalline alumina balls

This method is through the alimina ball in polyurethane tank,to provide the conditions for assessing the impact of grinding ball impact resistance,wear the nuit of time that the impact resistance of alumina ball.

1,An apparent size of qualified samples of alumina ball 4kg,grinding into cans,adding 4L water resistant impact test machine is grinding 80 cans per minute,2 hours to switch grinding,remove the sample water to clean,dry spare.

2,Weighing the processed sample on the balance.m

3,the sample into the tank,combined with the weight of the water,after sealing must not lesking into the water test machine so that grinding can turn 80 per minute,24-hour ground stop.

4,Four samples the removed from the grinding jar,washed with water,dried weight m

5,Measuring the average diameter of the ball

6,Calculation of the abrasion wear

Wear coefficient:g/kg h=(m1-m2)/m1/24أ—103

Equivalent wear(‰)EWT=KD(m1-m2)/m1

Empirical formula:Equivalent wear=Equivalent wearأ—Diamrter

Kupper

Kupper