- Kupper Cerambead

- Ceramsite Sand

- Alumina Ball

- High-purity Alumina

- Zirconia Toughened Alumina (ZTA)

- Alumina Tile, Brick,Cylinder

Latest news

- AFS Member Voices Industry’s Concerns

- OSHA Announces Final Rule on Silica Du

- Spherical Mold/Core Media Provides Hig

- Great Lakes Alumina Ball: Making littl

- Ferro Completes Acquisition of Italian

- Production of Nano-Crystalline Alumina

Contact us

- ADD: Shandong Province, China

- TEL:

- FAX:

- E-mail: sales@aluminachina.com

20-30 Mesh Ceramic Foundry Sand

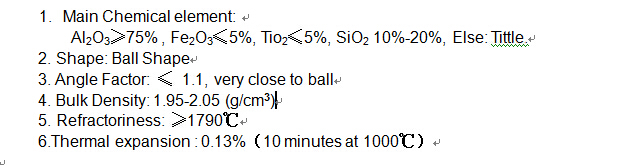

- Main Chemical Element: Al2O3≥75% , Fe2O3≤5%, TiO2≤5%, SiO2 5%-20%, other element: trace amounts;

- Shape: Ball shape;

- Angle Factor: ≤ 1.1, very close to ball shape;

- Thermal Expansion : 0.13% (10 minutes at 1000℃)

- Product description: Spherical with high strength and not easy to break

Product introduction

The 20-30 mesh ceramic foundry sand is used for the cleaning and polishing of copper and aluninum castings. Compared with the the price of chromite sand and zircon sand. It is easy to clean and won't stick to the castings.

Advantages: Particle size: 0.03 mm, fine and uniform particles, moderate hardness, high toughness, good self-sharpening, less consumption, can be recycled use, good performance for grinding of finished castings, stable chemical composition, abrasion, acid and alkali resistance.

Advantages: Particle size: 0.03 mm, fine and uniform particles, moderate hardness, high toughness, good self-sharpening, less consumption, can be recycled use, good performance for grinding of finished castings, stable chemical composition, abrasion, acid and alkali resistance.

Kupper ceramic foundry sand is spherical with high strength and not easy to break, which can greatly cut down production costs, avoid large amount of waste sand, increasing the sand reuse ratio. It greatly reduce the amount of sand loss.

PREVIOUSï¼ڑCeramsite sand for Polishing

NEXTï¼ڑ40 Mesh Ceramic Foundry Sand

Kupper

Kupper