- Kupper Cerambead

- Ceramsite Sand

- Alumina Ball

- High-purity Alumina

- Zirconia Toughened Alumina (ZTA)

- Alumina Tile, Brick,Cylinder

Latest news

- AFS Member Voices Industry’s Concerns

- OSHA Announces Final Rule on Silica Du

- Spherical Mold/Core Media Provides Hig

- Great Lakes Alumina Ball: Making littl

- Ferro Completes Acquisition of Italian

- Production of Nano-Crystalline Alumina

Contact us

- ADD: Shandong Province, China

- TEL:

- FAX:

- E-mail: sales@aluminachina.com

200 Mesh Coatings Foundry Sand

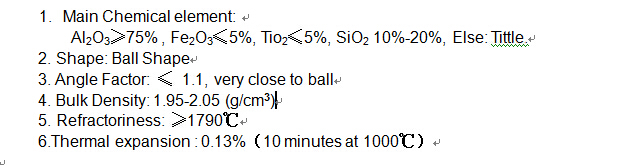

- Main Chemical Element: Al2O3≥75% , Fe2O3≤5%, TiO2≤5%, SiO2 5%-20%, other element: trace amounts;

- Shape: Ball shape;

- Angle Factor: ≤ 1.1, very close to ball shape;

- Thermal Expansion : 0.13% (10 minutes at 1000℃)

- Product description: Small gas evolution and Good coating performance.

Product introduction

The coastings foundry sand is a raw material for foundry coastings in the lost foam process(policast process), also known as foundry coasting sand. It is a fine sand, alias high alumina powder, which is filtered by 200 mesh screen.

Ingredients: alumina, bauxite as raw material, processed by high-temperature calcination, aluminum smelting, milling and selected with 200 mesh screen.

Production process of coated sand can be a dry blend method, cold coating method, temperature coating method and a thermal coating method four stages, but now the commonly used production method are thermal coating method.

Thermal coating process: Heat the raw sand to a certain temperature first, then mix it with the resin, solution and calcium stearate, cooling, crushing and screening. Different mixing system are adopted due to differences in formulation.

1. Prevent mechanical sticky sand and thermochemical sticky sand;

2. Good wettability and adhesion;

3. High temperature and strength;

4. Fast drying;

5. Small gas evolution;

6. Good coating performance.

Kupper

Kupper