- Kupper Cerambead

- Ceramsite Sand

- Alumina Ball

- High-purity Alumina

- Zirconia Toughened Alumina (ZTA)

- Alumina Tile, Brick,Cylinder

Latest news

- AFS Member Voices Industry’s Concerns

- OSHA Announces Final Rule on Silica Du

- Spherical Mold/Core Media Provides Hig

- Great Lakes Alumina Ball: Making littl

- Ferro Completes Acquisition of Italian

- Production of Nano-Crystalline Alumina

Contact us

- ADD: Shandong Province, China

- TEL:

- FAX:

- E-mail: sales@aluminachina.com

ceramsite for Lost Foam Casting

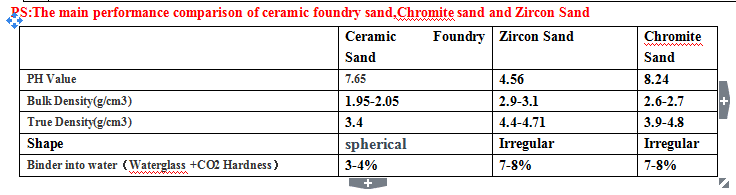

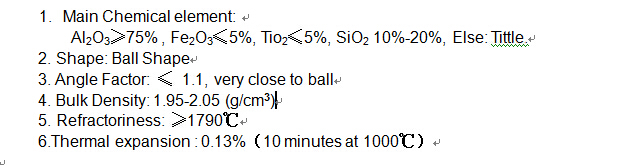

- Main Chemical Element: Al2O3≥75% , Fe2O3≤5%, TiO2≤5%, SiO2 5%-20%, other element: trace amounts;

- Shape: Ball shape;

- Angle Factor: ≤ 1.1, very close to ball shape;

- Thermal Expansion : 0.13% (10 minutes at 1000℃)

- Product description: high density, good thermal conductivity, high temperature resistance, workable with acid and alkali binder

Product introduction

The LFC molding sand is applied to the lost foam casting, which can improve the castings quality, cut down costs and make a better working environment.

Lost foam casting is a vacuum molding process with dry sand. During casting, many parts such as the angle of castings, elongated hole portion and complex interior compartment, etc. are likely to fail due to the sand vibrating, low refractory, sintered and sticky to the castings.

The 20 mesh LFC molding sand is a good lost foam process sand to avoid casting fails with the features of high density, good thermal conductivity, high temperature resistance, workable with acid and alkali binder, etc.

Application:

The LFC molding sand is suitable for many casting methods such as vacuum casting, VRH, LFC, investment casting, common sand (clay, sand, Na2Oآ·nSiO2 + CO2 sclerosis) and resin sand. It can be used with a variety of adhesives, greatly improving the quality of castings, also the sand is easy to clean.

With the development of the foundry industry and environment protection, Lost foam foundry sand are becoming more popular among casting plants. It has been hailed as environmentally friendly (GREEN BEADS) casting materials, with good use prospects.

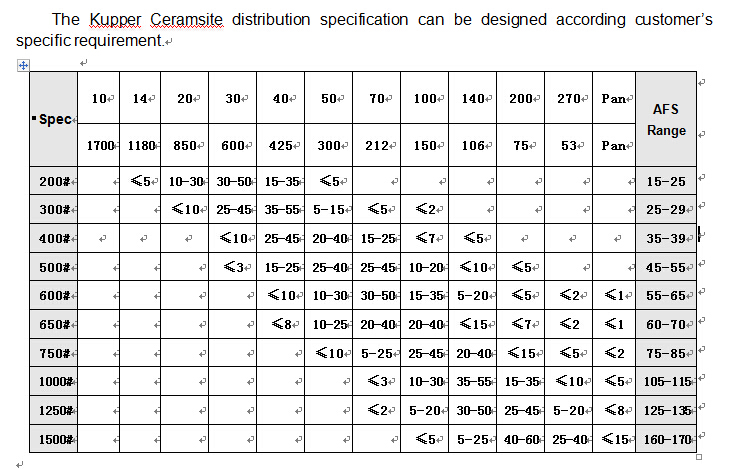

Kupper

Kupper